Para-aramid fibers, often synonymous with bulletproof vests and military applications, are poised to break free from their perceived limitations. While their ballistic protection remains unmatched, these remarkable synthetic fibers offer a unique blend of properties - exceptional strength, impressive thermal stability, outstanding chemical resistance, and remarkable resistance to abrasion and impact. This unique combination is propelling them beyond ballistics and into a diverse range of innovative applications across various industries.

Market Overview

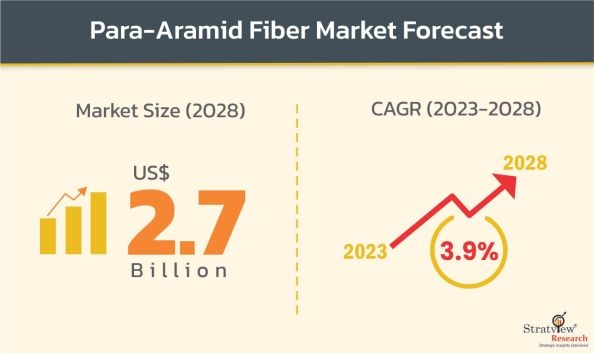

According to Stratview Research, the global para-aramid fiber market size is projected to reach USD 2.7 billion by 2028, growing at a CAGR of 3.9% during 2023-2028.

Unveiling the Powerhouse: Properties Driving New Frontiers

The exceptional properties of para-aramid fibers are the key to unlocking their potential in new applications:

- Unmatched Strength: Para-aramid fibers boast a tensile strength exceeding steel, making them ideal for applications requiring high load-bearing capacity.

- Thermal Resilience: These fibers exhibit exceptional resistance to heat and flames, making them suitable for high-temperature environments and fire-retardant materials.

- Chemical Fortitude: Para-aramid fibers display remarkable resistance to a wide range of chemicals, enabling their use in harsh industrial settings.

- Durability Defined: They offer exceptional resistance to abrasion and impact, ensuring extended product life and enhanced performance.

Emerging Applications: Pushing Boundaries

Para-aramid fibers are venturing beyond ballistic protection and finding exciting new applications in various sectors:

- Industrial Applications:

- Conveyor Belts: High-strength para-aramid belts can withstand heavy loads and harsh industrial environments, reducing downtime and maintenance costs.

- Gaskets and Seals: Their chemical resistance and high-temperature tolerance make them ideal for sealing applications in demanding industrial processes.

- Filtration Systems: Para-aramid filter bags offer superior strength and durability for filtering corrosive liquids and hot gases in industrial settings.

- Construction Industry:

- Reinforced Concrete: Para-aramid fibers can be integrated into concrete to improve its tensile strength and crack resistance, leading to safer and more durable structures.

- Earthquake-Resistant Construction: Their high strength-to-weight ratio makes them suitable for reinforcing building materials in earthquake-prone regions.

- Lightweight Construction Materials: Para-aramid composites can be used to create lightweight yet strong building components, enabling faster construction and reduced environmental impact.

- Emerging Technologies:

- Aerospace Composites: Para-aramid fibers, combined with other materials, can create lightweight and high-strength composites for aircraft components, leading to improved fuel efficiency and payload capacity.

- Space Exploration: Their heat resistance and durability make them suitable for components used in rockets and spacecraft.

- Smart Textiles: Para-aramid fibers can be integrated into textiles with embedded sensors, enabling applications in wearable technology and smart clothing.

Overcoming Challenges: A Sustainable Future

Despite their vast potential, the para-aramid fiber market faces certain challenges:

- Cost Considerations: The production process for para-aramid fibers is complex and energy-intensive, leading to a relatively high cost compared to some alternative materials.

- Sustainability Concerns: The manufacturing process can generate some environmental concerns. Manufacturers are increasingly focusing on sustainable practices and developing eco-friendly production methods.

- Limited Raw Material Availability: Reliance on specific precursors for production can lead to supply chain vulnerabilities and price fluctuations.

Looking Ahead: Innovation and Expansion

The future of the para-aramid fiber market is bright, driven by continuous advancements in fiber technology and a growing focus on sustainability:

- Research and Development: Ongoing research efforts are focused on developing new para-aramid fiber variants with tailored properties for specific applications.

- Cost-Effective Production: Technological advancements are aimed at streamlining the para-aramid fiber production process, reducing costs, and making them more competitive.

- Green Manufacturing: Sustainable practices and the use of recycled materials are gaining traction in para-aramid fiber production, minimizing environmental impact.

Conclusion

Para-aramid fibers are poised to revolutionize industries beyond ballistics. Their unique combination of properties and ongoing advancements are unlocking a world of possibilities. As research and development continue, we can expect to see these "miracle fibers" pushing boundaries and creating a more secure, efficient, and sustainable future across diverse applications.