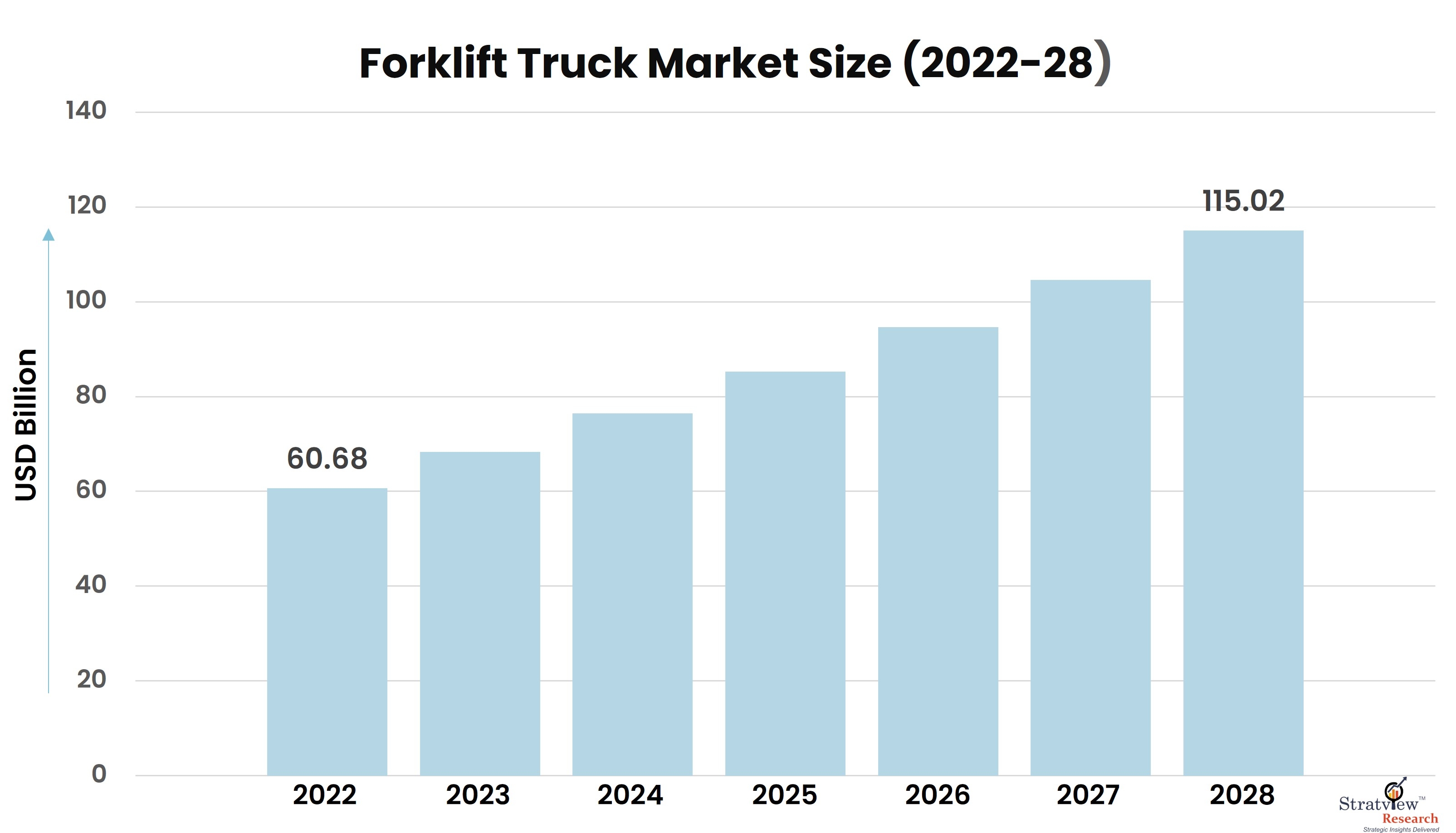

According to Stratview Research, the forklift truck market was estimated at USD 60.68 billion in 2022 and is likely to grow at a CAGR of 10.99% during 2023-2028 to reach USD 115.02 billion in 2028.

Forklifts are the backbone of material handling in numerous industries, from warehousing and manufacturing to construction and logistics. These versatile machines come in various types and configurations, each tailored to meet the specific needs of different sectors. Choosing the right forklift is a critical decision, and it requires careful consideration of your industry's requirements, workspace, and operational demands. In this buyer's guide, we'll explore the factors to consider when selecting the perfect forklift for various industries.

1. Warehouse and Distribution

Industry Needs: Efficient movement of goods, narrow aisle navigation, and the ability to stack and retrieve items from high shelves.

Recommended Forklifts:

Reach Trucks: Designed for narrow aisles, reach trucks are excellent for high stacking and retrieval in warehouses.

Electric Pallet Jacks: Ideal for fast-paced environments, electric pallet jacks enable quick and easy material transport.

Order Pickers: These forklifts have platforms for operators to pick orders directly from shelves.

2. Manufacturing

Industry Needs: Moving heavy materials and products efficiently within a confined workspace, often with an emphasis on durability.

Recommended Forklifts:

Counterbalance Forklifts: Versatile and suitable for a wide range of tasks, counterbalance forklifts are durable and powerful.

Pneumatic Tire Forklifts: These forklifts are designed for outdoor and indoor use and can handle rough terrain.

Electric Forklifts: For indoor manufacturing settings, electric forklifts offer quiet operation and emission-free handling.

3. Construction

Industry Needs: Handling heavy loads in rugged outdoor environments, often on uneven terrain.

Recommended Forklifts:

Rough Terrain Forklifts: These forklifts are built to handle off-road conditions, making them ideal for construction sites.

Telehandlers: With extended reach capabilities, telehandlers can perform tasks like lifting and placing loads at height.

4. Agriculture

Industry Needs: Handling large and heavy agricultural materials, such as bales, and working in muddy or uneven terrain.

Recommended Forklifts:

Agricultural Telehandlers: These specialized machines are designed for farm applications, featuring attachments for various agricultural tasks.

Rough Terrain Forklifts: Useful for lifting and transporting loads in outdoor farming environments.

5. Retail and Grocery

Industry Needs: Efficiently stocking and moving products in crowded retail spaces and ensuring the cleanliness and safety of the environment.

Recommended Forklifts:

Electric Pallet Jacks: Perfect for maneuvering through narrow store aisles and efficiently moving palletized products.

Stackers: Compact and versatile, stackers are suitable for organizing storage spaces and shelving in stores.

6. Maritime and Ports

Industry Needs: Handling cargo containers and heavy materials in large port environments.

Recommended Forklifts:

Container Handlers: These specialized machines are designed for lifting and transporting shipping containers.

Heavy-Duty Forklifts: Capable of handling the substantial weight of cargo containers and other port materials.

7. Cold Storage and Food Industry

Industry Needs: Maintaining hygiene and safely handling perishable goods in refrigerated and frozen environments.

Recommended Forklifts:

Cold Storage Forklifts: Designed to operate in sub-zero temperatures, ensuring the safe movement of goods in cold storage facilities.

Stainless Steel Forklifts: Resistant to corrosion and easy to clean, these forklifts are ideal for food and pharmaceutical industries.

8. Aerospace

Industry Needs: Safely transporting fragile and high-value aerospace components.

Recommended Forklifts:

Tow Tractors: Used for towing aerospace components in assembly lines and handling operations.

In all these industries, it's essential to consider factors such as load capacity, lifting height, power source (electric, diesel, LPG), and ergonomic features to ensure the safety and efficiency of your material handling operations.

In conclusion, selecting the right forklift for your industry is a decision that significantly impacts productivity and safety. By understanding your industry's specific requirements and the available forklift options, you can make an informed choice that optimizes your material handling processes and contributes to the success of your business.