Ultrasonic water level sensor are innovative devices that play a crucial role in measuring liquid levels accurately, efficiently, and non-invasively. These sensors utilize ultrasonic waves to determine the distance between the sensor and the liquid's surface, providing valuable information about the liquid level. In this article, we will delve into the workings of ultrasonic water level sensors and explore their diverse applications across different industries.

Principle of Operation:

Ultrasonic water level sensors operate based on the principle of echolocation. They emit high-frequency sound waves, typically ultrasonic waves beyond the range of human hearing, towards the liquid's surface. These waves then bounce back after hitting the liquid's surface and are detected by the sensor. The sensor calculates the time it takes for the sound waves to travel to the liquid's surface and back, and by knowing the speed of sound in the medium, it can accurately determine the distance between the sensor and the liquid surface.

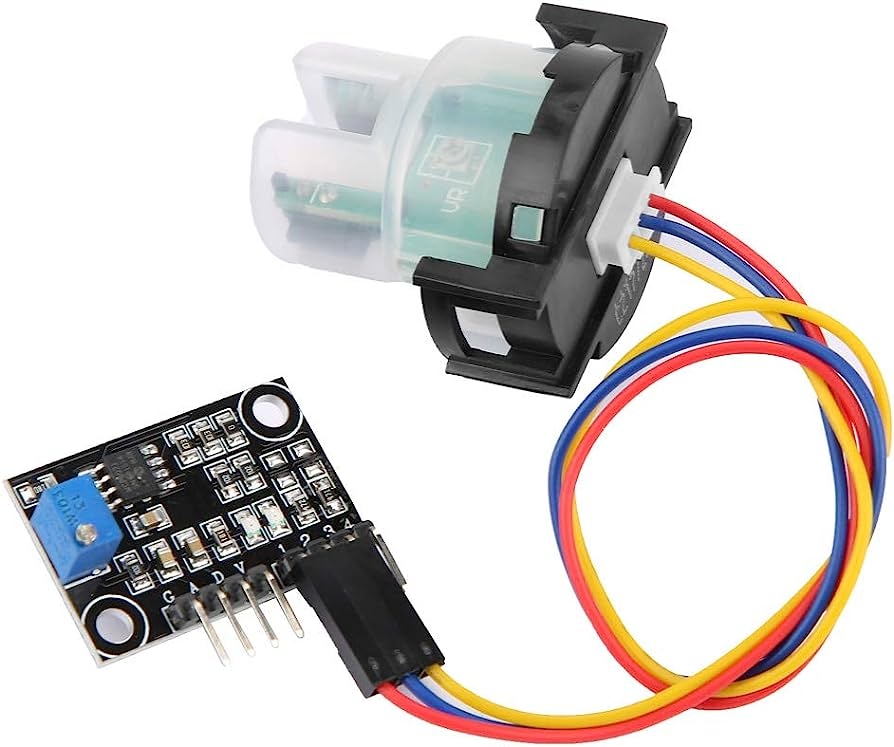

Components and Design:

These sensors typically consist of a transducer, which emits the ultrasonic waves, and a receiver, which captures the waves after they bounce back from the liquid surface. The distance measurement is often achieved using time-of-flight calculations. Ultrasonic sensors may also include additional components such as microcontrollers, signal processing units, and display interfaces for user-friendly data visualization.

Applications Across Industries:

1. Water Management: Ultrasonic water level sensors are extensively used in water management systems. They help monitor water levels in reservoirs, rivers, and lakes, providing critical data for flood prevention, irrigation, and water resource management.

2. Industrial Processes: Industries utilize these sensors to monitor liquid levels in tanks and vessels. They are crucial for ensuring proper inventory management, preventing overflows or shortages, and maintaining production efficiency.

3. Waste Water Treatment: In wastewater treatment plants, these sensors help control the levels of various liquids and chemicals used in the treatment process. This ensures that the treatment process is carried out efficiently and helps prevent environmental contamination.

4. Agriculture: Ultrasonic water level sensors find application in precision agriculture for monitoring water levels in irrigation systems. This enables farmers to optimize water usage and increase crop yield while conserving resources.

5. Automotive: In automotive applications, these sensors are used to measure fuel levels in tanks, helping drivers keep track of their fuel consumption and avoid running out of fuel during their journeys.

6. Home Automation: Ultrasonic water level sensors are also used in home automation systems for monitoring water levels in domestic tanks and cisterns. This can help homeowners save water and avoid potential water damage.

7. Marine Industry: In the marine industry, these sensors are used to measure the ballast and fuel levels in ships, ensuring safe and efficient navigation.

8. Chemical and Pharmaceutical Manufacturing: Ultrasonic water level sensors play a crucial role in chemical and pharmaceutical manufacturing processes, helping maintain precise liquid levels in various containers and reactors.

Advantages:

-

Non-contact Measurement: Ultrasonic water level sensors do not need to physically touch the liquid, which makes them ideal for measuring corrosive or hazardous substances.

-

High Accuracy: These sensors offer high precision and are not affected by factors like liquid color or turbidity.

-

Remote Monitoring: They allow for remote monitoring, making them suitable for unmanned or hard-to-reach locations.

-

Low Maintenance: Ultrasonic sensors are low-maintenance devices, as they do not have moving parts that can wear out quickly.

In conclusion, Ultrasonic water level sensor are versatile and reliable tools with applications spanning across numerous industries. Their ability to provide accurate and non-invasive liquid level measurements makes them indispensable for tasks ranging from water resource management to industrial process control and beyond. As technology continues to advance, these sensors are likely to become even more integral to various sectors, contributing to increased efficiency, sustainability, and safety.