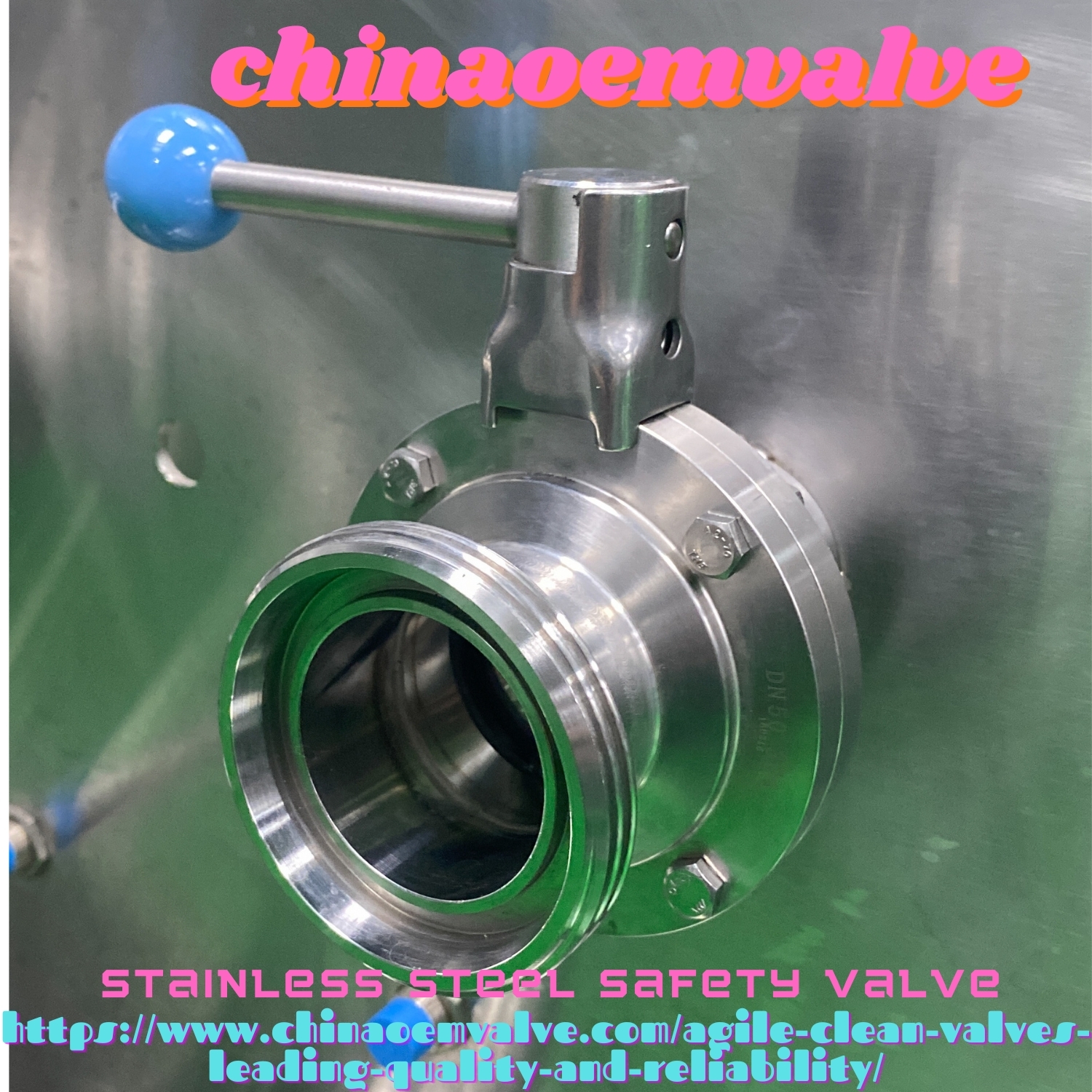

Stainless steel safety valve play a crucial role in ensuring the safety and reliability of industrial processes across a wide range of industries. These valves are engineered with specific design and operational features that make them indispensable for handling diverse applications where safety and performance are paramount concerns.

1. Corrosion Resistance: Stainless steel safety valves are crafted from high-quality stainless steel alloys, which offer exceptional corrosion resistance. This property is especially important in industries where the valve is exposed to corrosive substances, such as the chemical and petrochemical sectors. By resisting corrosion, these valves maintain their structural integrity over time, reducing the risk of failure.

2. High Temperature and Pressure Resistance: Industrial processes often involve extreme temperatures and pressures. Stainless steel safety valves are designed to withstand these harsh conditions without compromising their performance. They are frequently used in power generation, oil and gas, and manufacturing, where they help prevent overpressure incidents that can lead to catastrophic failures.

3. Reliability: Safety valves are the last line of defense against overpressure situations. Stainless steel safety valves are engineered for reliability, with features like tight sealing, durable springs, and precision machining. This reliability ensures that they activate when needed, preventing potentially dangerous pressure build-ups in equipment and pipelines.

4. Compliance with Industry Standards: Stainless steel safety valves are manufactured in compliance with stringent industry standards and codes. This includes standards like ASME (American Society of Mechanical Engineers) for pressure vessel safety. Adhering to these standards ensures that the valves meet the necessary performance and safety criteria.

5. Longevity: Stainless steel's durability contributes to the longevity of these safety valves. They have a longer service life compared to valves made from other materials, reducing the need for frequent replacement and maintenance. This not only saves costs but also minimizes downtime in industrial operations.

6. Versatility: Stainless steel safety valves are highly versatile and can be customized to suit specific application requirements. They come in various sizes and configurations, making them adaptable to a wide range of industrial processes, from small-scale applications to large-scale industrial facilities.

7. Easy Maintenance: While stainless steel safety valves are known for their longevity, they are also designed for ease of maintenance. This includes features like removable bonnets and simple maintenance procedures. This ease of maintenance ensures that valves can be quickly inspected, repaired, or replaced as needed.

8. Environmental Safety: Many industrial processes involve hazardous or toxic substances. Stainless steel safety valves help prevent the release of such substances into the environment, safeguarding the health and safety of workers and nearby communities. This environmental responsibility is a crucial aspect of modern industrial operations.

9. Pressure Relief Accuracy: These valves are engineered to provide precise pressure relief, ensuring that the pressure inside a vessel or system is controlled within safe limits. This accuracy is essential in preventing equipment damage, product contamination, and, most importantly, potential safety hazards.

In conclusion, Stainless steel safety valve are indispensable components in various industries, thanks to their corrosion resistance, high-temperature and pressure resistance, reliability, compliance with industry standards, longevity, versatility, ease of maintenance, environmental safety, and pressure relief accuracy. They contribute significantly to enhancing safety and performance in industrial processes, making them an essential asset for any operation where pressure control and safety are paramount concerns.

For more information visit chinaoemvalve.