In recent years, artificial intelligence (AI) has emerged as a game-changer in the manufacturing industry, revolutionizing traditional processes and driving unprecedented levels of efficiency and innovation. From predictive maintenance to supply chain optimization, AI is reshaping every aspect of manufacturing, propelling the industry into the era of Industry 4.0.

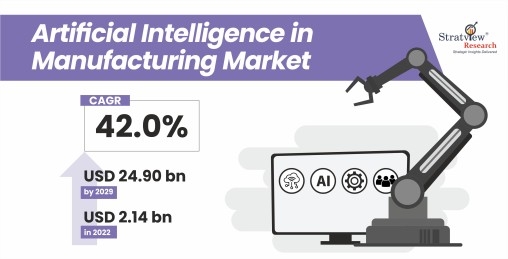

The global artificial intelligence in manufacturing market is expected to grow from USD 2.14 billion in 2022 to USD 24.90 billion by 2029 at a CAGR of 42.0% during the forecast period.

One of the most significant contributions of AI to manufacturing is predictive maintenance. By leveraging machine learning algorithms to analyze equipment data in real-time, manufacturers can anticipate potential issues and schedule maintenance proactively. This predictive approach minimizes downtime, reduces maintenance costs, and extends the lifespan of equipment, leading to substantial savings and increased productivity.

AI-powered robotics is another transformative technology that is redefining manufacturing automation. Collaborative robots (cobots), equipped with advanced vision systems and machine learning capabilities, can work alongside human workers with unparalleled precision and adaptability. This collaboration not only accelerates production cycles but also enhances workplace safety by automating repetitive or hazardous tasks.

Supply chain optimization is yet another area where AI is driving significant benefits for manufacturers. By analyzing vast amounts of data related to inventory levels, supplier performance, and market demand, AI algorithms can optimize inventory management, streamline procurement processes, and minimize supply chain disruptions. This enables manufacturers to achieve greater agility and responsiveness to changing market conditions, ultimately enhancing customer satisfaction and profitability.

Moreover, AI is empowering manufacturers to unlock new frontiers of product innovation through generative design and simulation. By harnessing AI algorithms to explore countless design iterations and simulate performance under various conditions, engineers can create highly optimized and innovative products that meet customer needs while minimizing material waste and environmental impact.

In conclusion, the integration of artificial intelligence into manufacturing processes is driving a paradigm shift in the industry. Manufacturers that embrace AI technologies stand to gain a competitive edge by unlocking new levels of efficiency, flexibility, and innovation. As AI continues to evolve, its impact on manufacturing will only grow, ushering in a new era of unprecedented growth and opportunity for the industry.