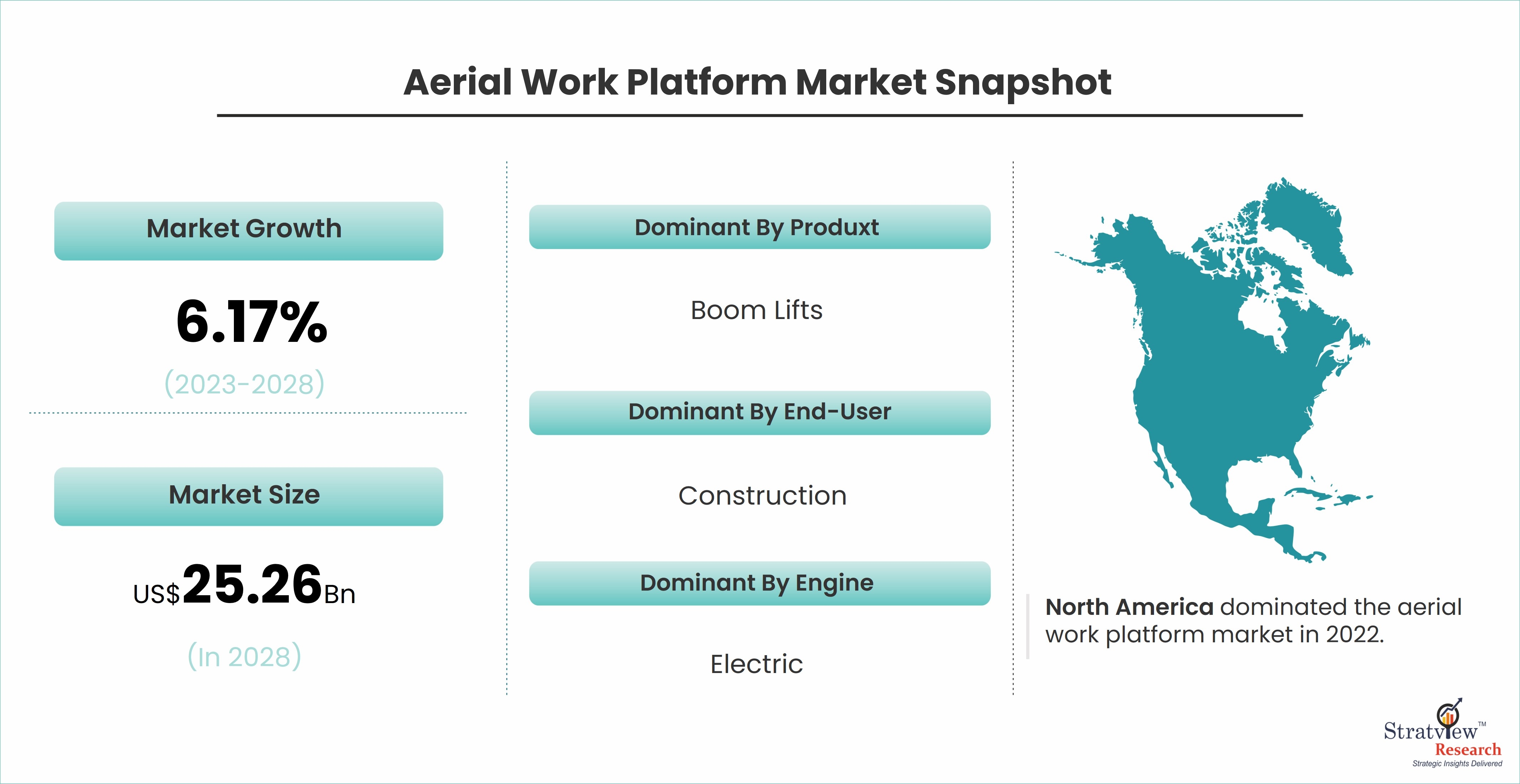

According to Stratview Research, the aerial work platform market was estimated at USD 17.59 billion in 2022 and is likely to grow at a CAGR of 6.17% during 2023-2028 to reach USD 25.26 billion in 2028.

In the realm of construction, maintenance, and various industrial sectors, there's a constant demand for safer and more efficient solutions for working at height. Among the key innovations that have transformed these industries is the evolution of aerial work platforms (AWPs), which have significantly improved access to elevated work areas while enhancing safety and productivity. From humble beginnings to cutting-edge technologies, the journey of aerial work platforms reflects a remarkable evolution, driven by advancements in engineering, safety standards, and industry demands.

The Early Days: Origins and Innovation

The concept of aerial work platforms can be traced back to the early 20th century when basic scaffolding and ladders were the primary means of accessing elevated work areas. However, as industrialization and urbanization accelerated, the need for safer and more efficient solutions became apparent. In response, the first rudimentary aerial work platforms, such as scissor lifts and bucket trucks, emerged to meet the growing demand.

These early AWPs were relatively simple in design, often consisting of hydraulic or mechanical lifting mechanisms mounted on mobile platforms. While effective for certain applications, they lacked the versatility and sophistication of modern aerial work platforms. Nevertheless, they laid the foundation for further innovation and development in the industry.

Technological Advancements: The Rise of Modern AWPs

The latter half of the 20th century witnessed significant advancements in aerial work platform technology, driven by improvements in hydraulic systems, materials, and manufacturing processes. Hydraulic scissor lifts, articulated boom lifts, and telescopic boom lifts became commonplace, offering greater reach, maneuverability, and load capacities.

The integration of electronic controls and safety features further enhanced the functionality and safety of aerial work platforms. Innovations such as proportional control systems, tilt sensors, and self-leveling platforms improved operator comfort and control, while safety interlocks and emergency descent systems provided added layers of protection for personnel working at height.

Moreover, the emergence of lightweight materials such as aluminum and fiberglass contributed to the development of compact and portable AWPs suitable for indoor and outdoor use. These advancements expanded the applications of aerial work platforms beyond construction and maintenance, encompassing industries such as warehousing, logistics, and event management.

Safety Standards and Regulations: Ensuring Worker Protection

As the use of aerial work platforms became more widespread, concerns regarding operator safety and equipment reliability prompted the development of industry standards and regulations. Organizations such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) established guidelines and requirements for the design, operation, and maintenance of AWPs, ensuring compliance and promoting best practices in the industry.

Safety features such as guardrails, harness attachment points, and emergency stop buttons became standard requirements for aerial work platforms, prioritizing the protection of personnel working at height. Regular inspections, maintenance, and operator training programs were also implemented to mitigate risks and prevent accidents associated with AWP operation.

The Future of Aerial Work Platforms: Innovations and Trends

As we look ahead, the evolution of aerial work platforms shows no signs of slowing down. Emerging technologies such as electric propulsion, lithium-ion batteries, and advanced sensors are reshaping the landscape of AWPs, making them more energy-efficient, environmentally friendly, and autonomous. Electric aerial work platforms offer quieter operation, zero emissions, and lower operating costs compared to their diesel-powered counterparts, aligning with sustainability initiatives and regulations.

Furthermore, the integration of telematics systems and IoT-enabled devices enables remote monitoring, diagnostics, and predictive maintenance of aerial work platforms, maximizing uptime and reducing downtime. Autonomous features such as obstacle detection, collision avoidance, and automated positioning systems enhance safety and efficiency, allowing operators to focus on tasks while the AWP handles navigation and positioning.

In conclusion, the evolution of aerial work platforms represents a remarkable journey of innovation, safety, and progress. From humble beginnings to sophisticated machines, AWPs have revolutionized the way we work at height, providing safe, efficient, and versatile solutions for a wide range of industries. As technology continues to advance and industry demands evolve, the future of aerial work platforms promises even greater heights, with innovations that empower workers to rise above challenges and reach new levels of productivity and safety.