A vacuum pump known as a cryogenic pump collects gases by causing them to condense on a surface that has been chilled to an extremely low temperature of around 120 K. However, the boiling and freezing temperatures of the gases involved have a significant impact on the pump's performance.

These pumps are widely used for handling, moving, and transferring cryogenic fluids such as liquid hydrocarbons, oxygen, nitrogen, hydrogen, and argon. The use of cryogenic pumps is a need as the need for liquid gases rises across several sectors.

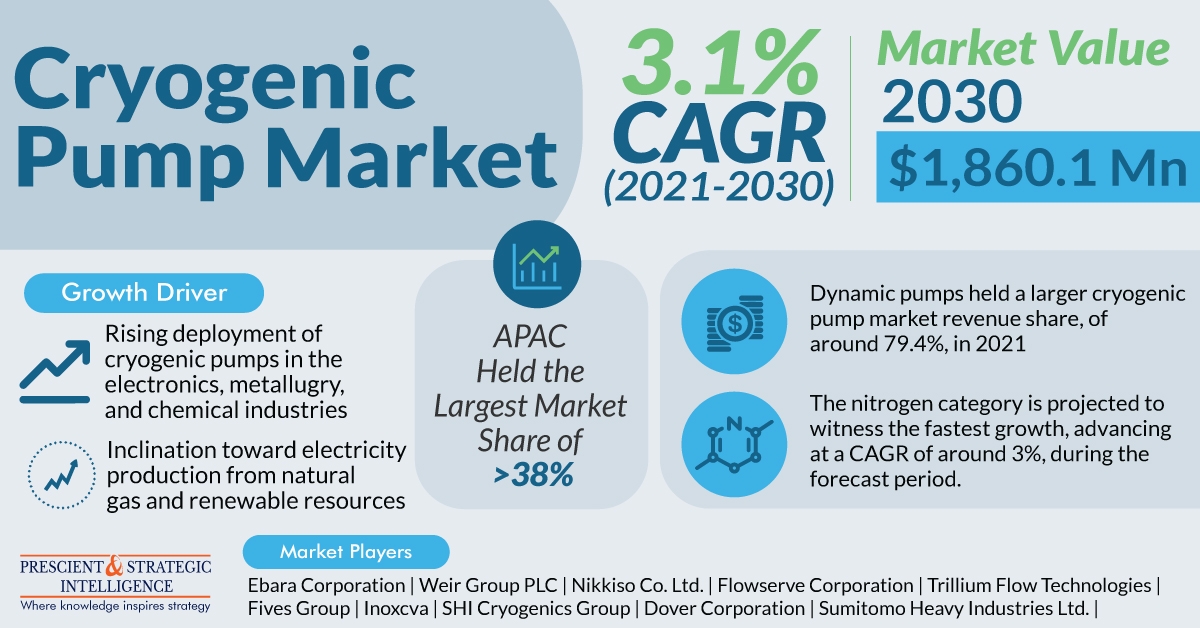

The global cryogenic pump market is expected to reach $1,860.1 million by 2030. The expanding use of such pumps in the metallurgy, electronics, and chemical sectors is a key factor driving the market.

Additionally, the expansion of the industry is being driven by a rise in investment throughout the power generating industry along with a preference for producing electricity from natural gas and other resources to reduce carbon footprint.

Fastest Growth Will be Seen in Nitrogen Category

In the coming years, the nitrogen category is predicted to increase at the quickest rate, with a CAGR of almost 3%. This is mostly due to the frequent usage of nitrogen gas during plant maintenance and the preparations made by petrochemical and refinery businesses for startup and shutdown.

Thus, the use of cryogenic pumps for capturing the gas and its vapor from the ground is escalating due to the expanding demand for nitrogen gas in various industries, including metallurgy, oil & gas, and healthcare.

Widespread Use of Dynamic Pumps

Due to their superior qualities, low maintenance requirements, extended lifespan, and high efficiency, dynamic pumps hold a larger revenue share of the cryogenic pump market, at about 79.4%.

Additionally, the market will expand due to the surge in requirements for such pumps from the energy, shipbuilding, and healthcare sectors.

This pump also loads gaseous medications into medical bottles and cryogenic cylinders. Sales of these pumps increased during the COVID-19 epidemic due to the significant need for medical oxygen in numerous nations worldwide. Additionally, these pumps are employed in several industrial processes, including filling LNG and CO2.

Why Was APAC the Leader?

In 2021, APAC had the highest market revenue ($538.2 million), and it is anticipated that it will continue to dominate the sector. The main causes of this include the region's increasing urbanization, the expansion of industries like energy & power and metallurgy in India, China, and Japan, and the rising demand for energy in all member nations.

Additionally, the Indian government is working to guarantee a constant power supply. The nation must improve its mechanisms for generating power to meet this goal. The government is putting more emphasis on natural gas-fired power plants as a result, so demand for cryogenic pumps is anticipated to rise in the years to come.

Rising Chemical and Petrochemical Sector Demand

Cryogenic pumps are also widely employed in the petrochemicals and chemicals industry for various applications, including sulfur recovery, cold reactors, oxidation processes, coal gasification, and regenerative catalysis.

The increased demand for different petrochemicals and chemicals worldwide is to blame for this. For example, it is anticipated that the manufacturing capacity of petrochemicals will rise from 2,214.9 million tons per year (mtpa) in 2020 to 3,103.6 mtpa in 2030.