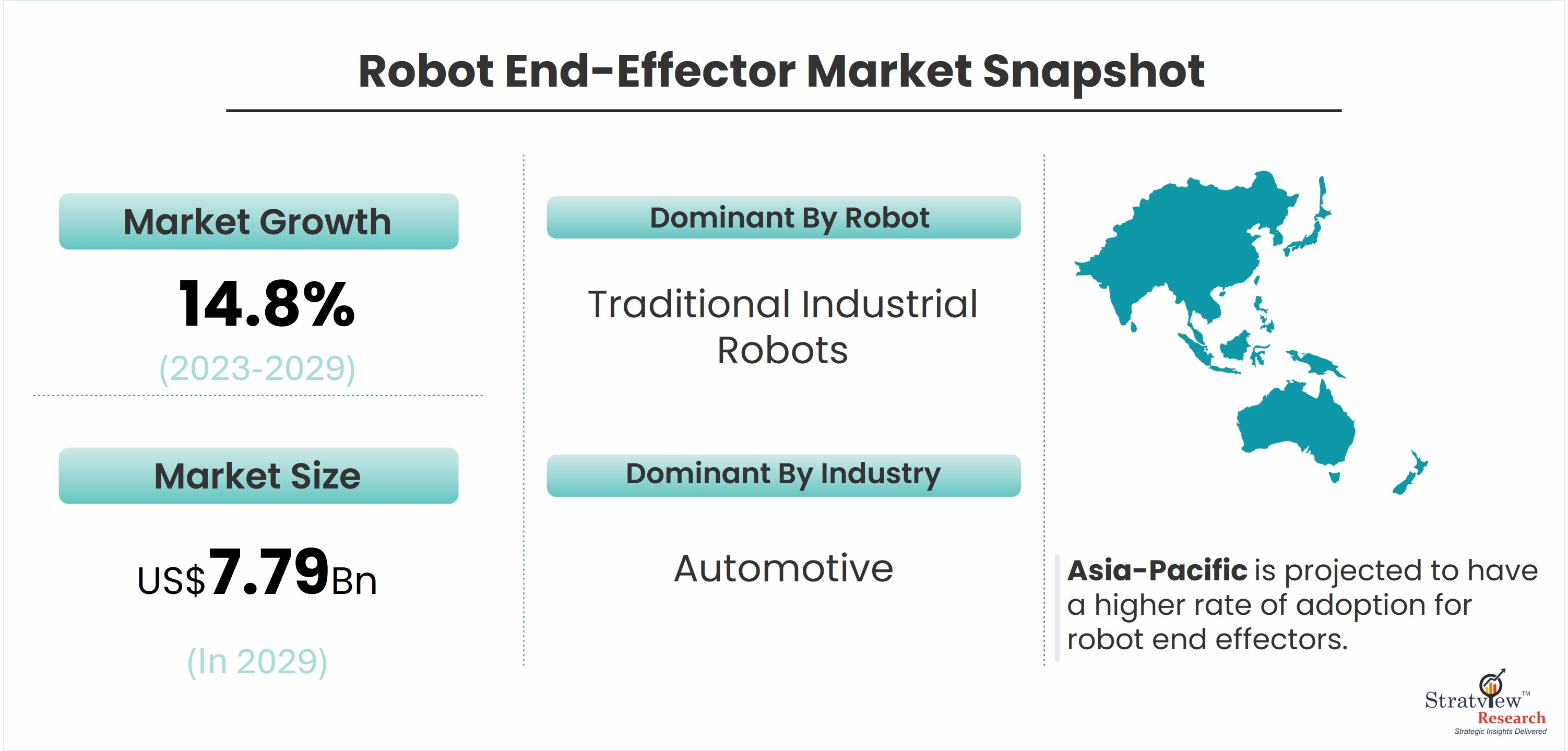

According to Stratview Research, the robot end-effector market was estimated at USD 2.97 billion in 2022 and is likely to grow at a CAGR of 14.8% during 2023-2029 to reach USD 7.79 billion in 2029.

In the ever-evolving landscape of industrial automation, the Robot End-Effector Market stands as a testament to the relentless pursuit of innovation. As industries across the globe seek to enhance efficiency, accuracy, and adaptability in their automated processes, the spotlight on advancements in robot end-effectors becomes increasingly crucial. This article navigates through the dynamic terrain of the Robot End-Effector Market, uncovering the latest innovations that are reshaping the future of automation.

The Role of Robot End-Effectors:

At the heart of automated precision lies the robot end-effector, a sophisticated tool designed to execute specific tasks with accuracy and efficiency. From gripping and handling to welding and painting, end-effectors play a pivotal role in transforming the capabilities of robotic systems. As industries continue to push the boundaries of automation, the market responds with cutting-edge innovations that redefine the possibilities of what these robotic tools can achieve.

Key Innovations Driving Market Dynamics:

Smart and Adaptive Gripping Technology: Traditional gripping mechanisms are giving way to smarter, more adaptive solutions. Innovations in gripping technology now include sensors, cameras, and AI algorithms that enable robots to adapt their grip based on the shape, size, and fragility of objects. This not only enhances efficiency in handling diverse items but also reduces the risk of damage during the process.

Force and Tactile Feedback Systems: The integration of force and tactile feedback systems empowers robots with a sense of touch. This innovation allows robots to interact with their environment more delicately, adjusting force and pressure based on real-time feedback. Industries such as electronics manufacturing and quality control benefit from this heightened sensitivity, enabling robots to handle delicate materials with unprecedented precision.

Dual-Arm and Collaborative Robotics: The rise of collaborative robots (cobots) has transformed the dynamics of human-robot interaction. Dual-arm systems and collaborative robotic solutions are gaining traction, allowing robots to work alongside human operators seamlessly. This trend not only enhances flexibility in manufacturing but also opens up new avenues for intricate and collaborative tasks.

IoT Integration and Connectivity: The Internet of Things (IoT) is permeating the Robot End-Effector Market, fostering connectivity and real-time data exchange. End-effectors equipped with IoT capabilities can communicate with other components in the automation system, enabling predictive maintenance, remote monitoring, and data-driven optimization of robotic processes.

Market Applications:

The innovations in the Robot End-Effector Market find applications across diverse industries:

Automotive Manufacturing: Precision in robotic assembly lines, welding, and material handling is crucial for the automotive industry, where end-effectors contribute to streamlined and efficient production processes.

Electronics and Semiconductor Production: Delicate tasks such as pick-and-place operations and circuit board assembly benefit from advanced end-effectors with precise gripping and sensing capabilities.

Food and Beverage Processing: Hygienic and adaptable end-effectors are essential in the food industry, ensuring safe handling and packaging of various products.

Pharmaceutical and Medical Devices: In pharmaceutical manufacturing, end-effectors with stringent cleanliness and precision requirements play a vital role in tasks such as dispensing, sorting, and packaging.

Challenges and Future Prospects:

While the Robot End-Effector Market is flourishing with innovations, challenges such as the complexity of integration, high initial costs, and the need for skilled technicians persist. However, as technology matures and the demand for automation grows, these challenges are expected to be addressed, paving the way for a more accessible and efficient market.

Conclusion:

As industries navigate the complexities of automation, the Robot End-Effector Market stands as a beacon of innovation, driving the transformative capabilities of robotic systems. The continuous evolution of gripping technologies, sensing mechanisms, and collaborative solutions propels automation into new frontiers. Navigating this dynamic market not only requires a keen understanding of the latest innovations but also a commitment to embracing the limitless potential of robot end-effectors in shaping the future of industrial automation.