Microelectromechanical systems, commonly known as MEMS, are tiny systems that combine electrical and mechanical components. Though minuscule in size, ranging from micrometers to millimeters, MEMS have revolutionized various industries with their innovative sensing and actuation capabilities.

What are MEMS?

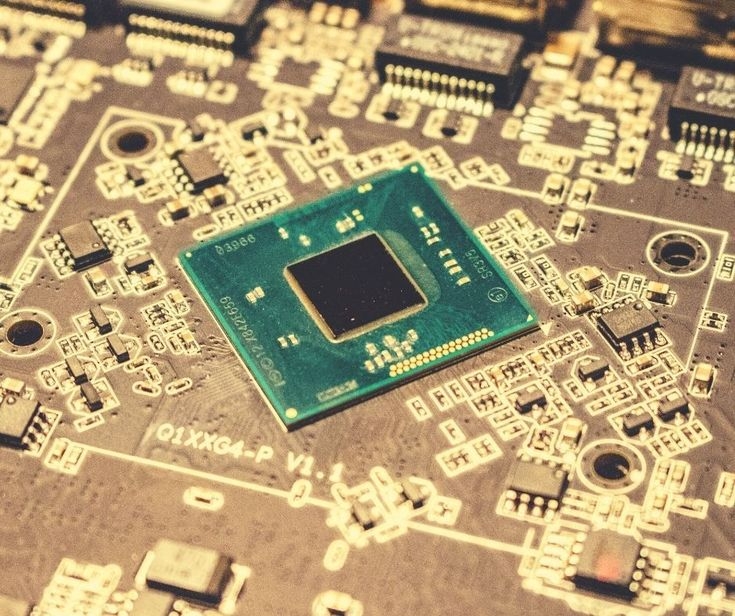

MEMS are miniature devices and systems that are made up of components between 1 to 100 micrometers in size (100 micrometers is about the diameter of a human hair). MEMS devices usually consist of a central unit that senses or controls motion on a micro scale. This central unit is made up of a micro-sensor, micro-actuator and the associated control electronics. The electronics integrate the sensing and actuation functions into a microchip. At their most basic level, MEMS use electricity to power mechanical movements and devices.

MEMS leverages microfabrication techniques developed by the integrated circuit (IC) industry to mass produce microscopic devices. Similar to ICs, MEMS are fabricated using technologies such as lithography, etching, thin or thick film deposition and electroforming to build microstructures out of silicon, ceramics and polymers. This allows complex micromechanical structures and features to be manufactured in large volumes at low costs.

Examples of MEMS technology

Some common examples of Microelectromechanical systems technologies that have become ubiquitous include:

- Accelerometers: Present in airbags, smartwatches and smartphones to detect movement and orientation. Car and aircraft accelerometers detect G-forces.

- Gyroscopes: Used in automotive applications for stability control and navigation systems. Also found in consumer electronics for motion gaming.

- Pressure sensors: Monitor tire pressure, measure blood pressure and are used in biomedical and industrial applications.

- Micromirror devices: Used in advanced scanning and projection displays like DLP projectors and head-up displays.

- Microfluidic chips: Automate chemical and biological analysis, drug screening and DNA research. Powered by MEMS pumps and valves to manage liquids at microscale levels.

- Inkjet printheads: Key component in modern inkjet printers, responsible for precision ejection of ink droplets in the printing process.

Widespread applications of MEMS

Due to their versatile sensing and actuation properties, MEMS have found use across various industries from consumer electronics to healthcare. Some major application areas include:

Automotive: Airbag deployment systems, tire pressure monitoring, engine management systems, autonomous vehicle sensors, navigation and stability controls rely heavily on MEMS.

Consumer electronics: Used in smartphones, laptops, gaming consoles, cameras for functionality like gesture recognition, image stabilization and augmented reality applications.

Medical: Implantable medical devices, surgical instruments, point-of-care diagnostics, heart rhythm monitoring, drug delivery and prosthetics have benefited from miniaturized MEMS.

Industrial: Gas and flow sensors for process control, building automation, motion and vibration sensors for manufacturing machinery are some industrial applications.

Aerospace: Aircraft instruments, engine sensors, navigation systemsspace equipment, guided missiles employ MEMS technologies.

Future prospects of MEMS

With continued research and development, MEMS are poised to become more prevalent in our everyday lives going forward:

- Internet of Things (IoT): Tiny MEMS sensors will power a multitude of smart, connected devices and applications envisioned under IoT.

- Lab-on-a-chip: Integrated microfluidic MEMS devices for performing complete laboratory experiments and analyses on a single chip.

- Wearables and implantables: Advanced, tiny biosensors and interfaces will fuel next-gen wearable and implantable technologies.

- Smart cities: Environmental and infrastructure monitoring solutions employing distributed MEMS mesh networks.

- Electric vehicles: From motor controls to battery monitoring, EVs provide opportunity for innovative MEMS.

Thus, MEMS will play a critical role in enabling the technologies of tomorrow with their diminutive yet disproportionately large impact on how we live and interact with technology. Overall, MEMS are set to revolutionize numerous industries and applications thanks to the marvel of micro-engineering.

Get more insights on this topic: https://www.newsanalyticspro.com/microelectromechanical-systems-the-tiny-revolution/