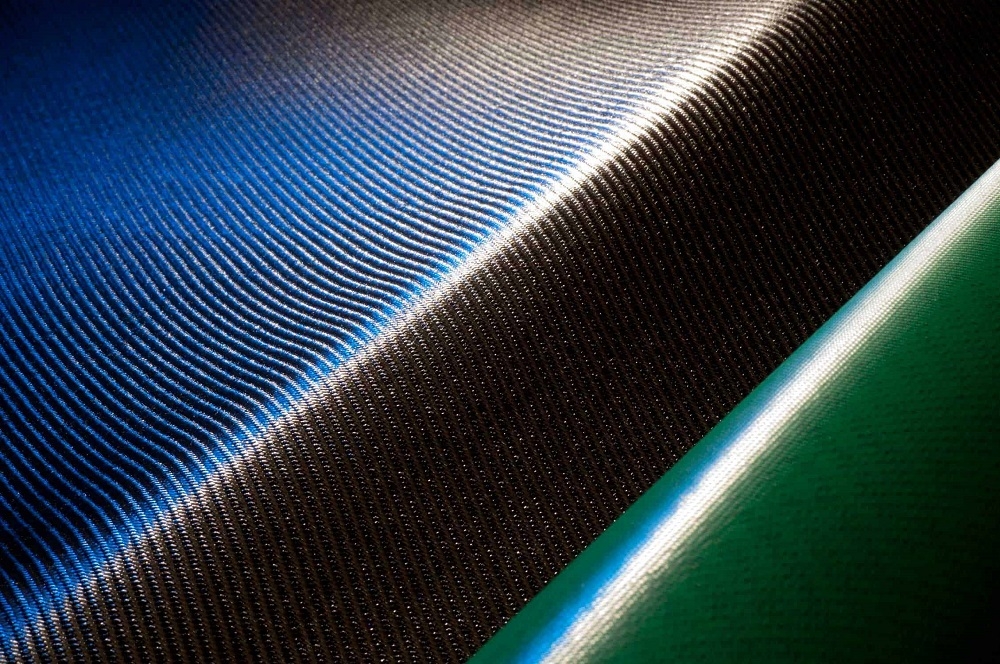

Carbon prepreg or carbon fiber preimpregnated composite is a lightweight composite material made by impregnating carbon fibers with a resin such as epoxy, phenolic, or bismaleimide. It has exceptional strength, modulus, and fatigue resistance properties. Carbon prepreg materials are widely used in aerospace, automotive, wind energy, sporting goods, and other industries where high strength to weight ratio is important. In aerospace industry, carbon prepreg is used to manufacture aircraft components like fuselage panels, floor beams, bulkheads, stringers and wing skins to reduce aircraft weight.

The global carbon prepreg market is estimated to be valued at US$ 9728 Mn in 2024 and is expected to exhibit a CAGR of 5.9% over the forecast period 2024 to 2031, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

Increasing demand from aerospace industry is one of the major drivers of the carbon prepreg market. Strict regulations around the world are pushing aircraft manufacturers to use lightweight composite materials in aircraft manufacturing to improve fuel efficiency and reduce carbon emissions. Carbon prepregs help reduce aircraft weight by 10-30% compared to traditional aluminum. Due to this, their use in primary aircraft structures like fuselage and wings has increased significantly in new aircraft programs. Furthermore, increasing procurement of military aircraft and space launch vehicles by defense organizations worldwide is also fueling the demand for carbon prepregs from the defense sector. Carbon prepregs are easier to mold than dry carbon fabrics and provide better mechanical properties to finished parts. This advantage is boosting their adoption over dry fabrics in end use industries.

SWOT Analysis

Strength: Carbon Prepreg has high mechanical strength and modulus which makes it preferable for aerospace and defense applications. Its light-weight property helps reduce structural weight of components by 30-40%. It also offers dimensional stability and reproducibility during manufacturing.

Weakness: Carbon Prepreg has a limited shelf life and requires strict storage conditions. Any damage or contamination during storage and handling can affect its mechanical properties. The manufacturing process of Carbon Prepreg is complex and expensive compared to traditional composites.

Opportunity: Increasing demand for fuel-efficient vehicles is driving the use of lightweight materials like Carbon Prepreg in the automotive industry. Growing aerospace sector in developing nations such as India and China is opening new markets. Development of out-of-autoclave curing processes can reduce production costs.

Threats: Availability of cheaper alternative composites can hamper the market growth. Economic slowdowns can impact the aerospace and defense sectors which are major end-users. Strict environmental regulations around VOC emissions during manufacturing pose a challenge.

Key Takeaways

The Global Carbon Prepreg Market Size is expected to witness high growth over the forecast period of 2024 to 2031.

Asia Pacific region dominates currently due to presence of large automotive and aerospace manufacturing bases in China, Japan and India. Countries like China and India are witnessing fastest market growth due to increasing investments in domestic aviation sector.

Key players operating in the Carbon Prepreg market are 3M, Arkema Group (Bostik SA), H.B. Fuller Company, Henkel AG & Co. KGaA, Master Bond Inc., Nexus Adhesives, Permabond LLC, Pidilite Industries Ltd, Sika AG, and Threebond International Inc. The major players are focusing on new product launches, partnerships and capacity expansion strategies to strengthen their market position.

Get more insights on this topic: