Market Dynamics:

Increasing demand for flame retardant electronics applications is the primary driver propelling the growth of the global cyanate ester resins market. Cyanate ester resins provide superior flame retardant properties as compared to conventional resins and find increasing usage in fabrication of circuit boards and other electronic components where flame retardancy is an important consideration. Additionally, growing aerospace industry has augmented the demand for cyanate ester resins owing to their ability to retain strength and rigidity even at high temperatures making them suitable for use in aircraft components. However, the market growth could be hampered by the relatively higher cost of cyanate ester resins as compared to conventional thermoset resins.

SWOT Analysis

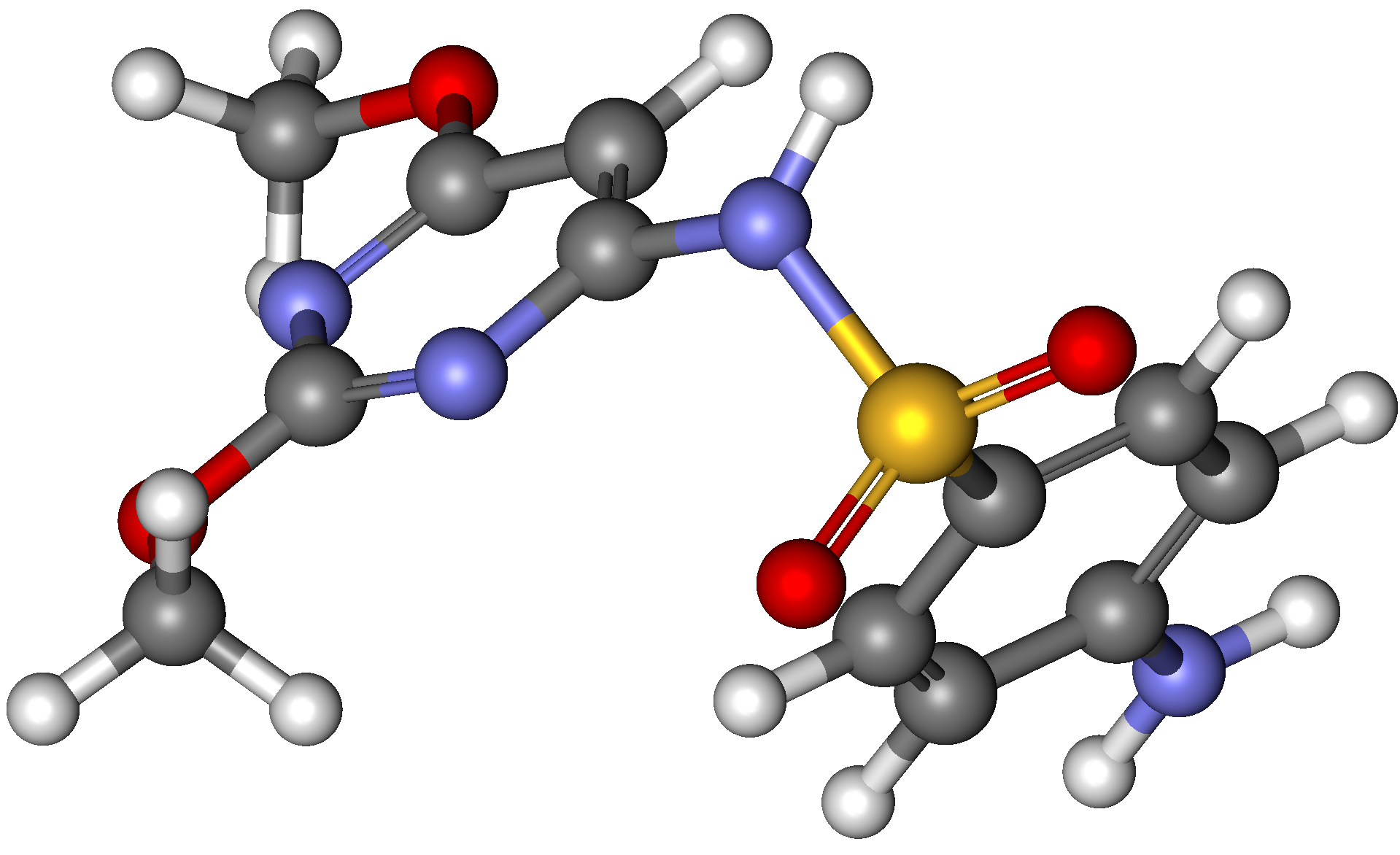

Strength: Cyanate ester resins provide high heat resistance making them suitable for applications in aerospace, electronics and defense industries. Their unique molecular structure provides high glass transition temperature, low dielectric constant and very low moisture absorption. They are highly resistant to heat, chemicals and radiation. Their combination of properties make them a suitable alternative to toughened epoxy resins.

Weakness: Cyanate ester resins require higher curing temperature compared to epoxy resins. This makes their processing more complex and energy intensive. They also have relatively high material and processing cost compared to epoxy resins which limits their use in cost-sensitive applications.

Opportunity: Growing demand for high performance composites from aerospace, electronics and defense industries due to stricter regulation on fuel efficiency and emission norms is driving the demand for cyanate ester resins. They can potentially replace toughened epoxy resins in applications requiring optimum balance of mechanical, thermal and electrical properties. Developments of new formulations at lower curing temperatures can help reduce production costs and drive its adoption in new applications.

Threats: Availability of other alternatives like bismaleimide and Polyphenyl ether resins which also offer high heat resistance poses competition to cyanate ester resins. Economic slowdowns can impact the highly capital intensive aerospace, electronics and defense industries negatively affecting the demand for high performance resins. Volatility in raw material prices like BPA and hydrogenated bisphenol A can increase the overall cost of cyanate ester production.

Key Takeaways

The Global Cyanate Ester Resins Market Size is expected to witness moderate growth over the forecast period of 2019-2029. Expanding aerospace industry along with growing demand for electronics and defense equipment is projected to drive the consumption of cyanate ester resins.

Regional analysis: North America region currently dominates the cyanate ester resins market owing to large presence of aerospace manufacturers in countries like United States. Europe and Asia Pacific also contribute significantly to the global demand due to sizable aircraft component manufacturing industry. Asia Pacific region is likely to witness fastest growth on account of increasing aircraft production and electronic good exports from China and other southeast Asian countries.

Key players: Key players operating in the cyanate ester resins market are Huntsman, Lonza, Cyanate Solutions, TenCate, Cytec Solvay Group. Huntsman is one of the largest producer of cyanate ester resins worldwide with wide product portfolio for applications in aerospace composites, printed circuit boards, insulation and molding compounds. Other major players like Cytec Solvay Group and Lonza specialize in high performance resins for aerospace components and space applications.

Explore more information on this topic, Please visit-

https://www.rapidwebwire.com/cyanate-ester-resins-market-size-and-share-analysis-growth-trends-and-forecasts/