A flow control ball valve stands out in the realm of fluid control mechanisms due to its innovative design, which harmoniously blends simplicity with exceptional efficiency. This design enables it to be a top choice for numerous industrial applications, ensuring precise flow regulation and long-term reliability.

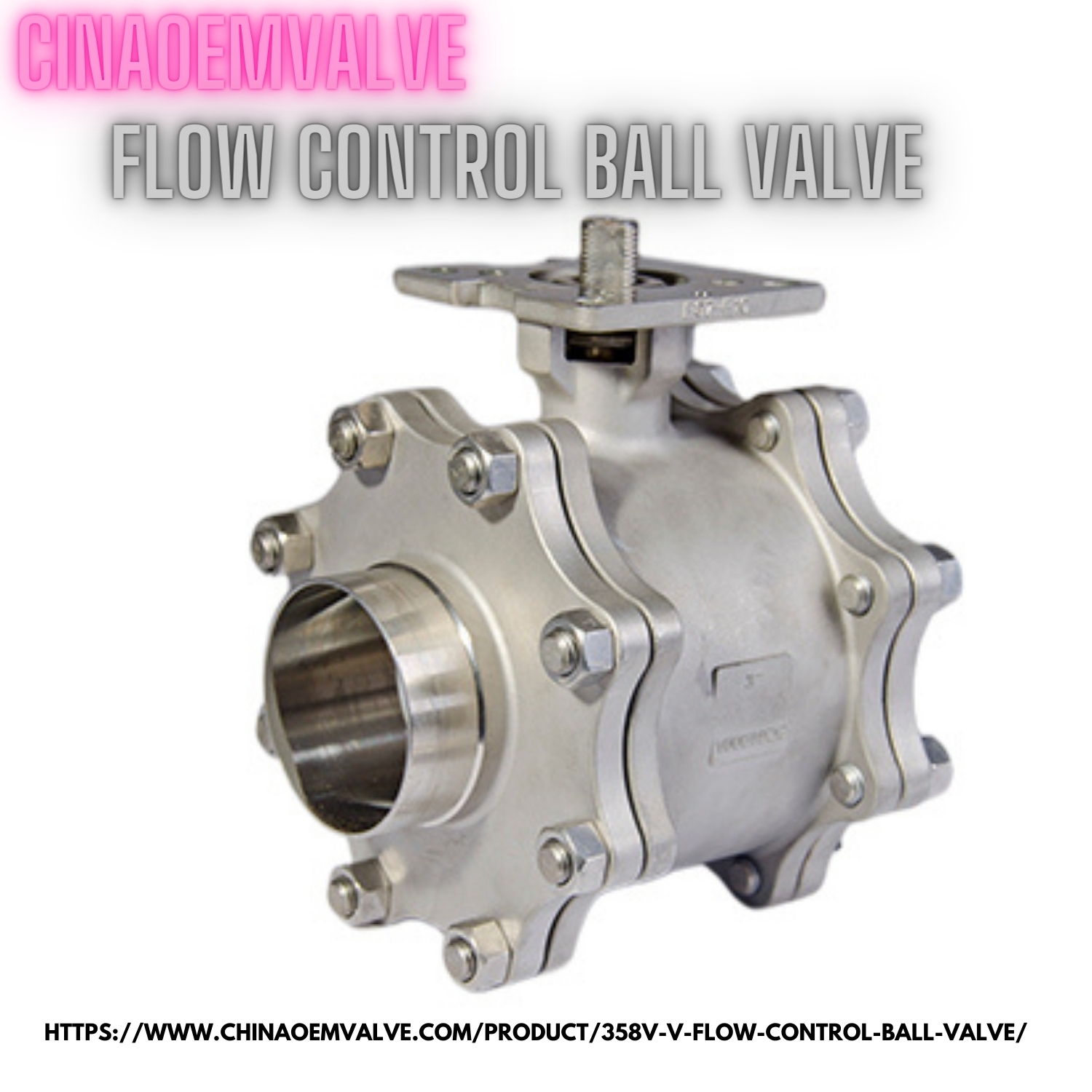

The unique construction of a flow control ball valve features a spherical closure element, often made of materials like stainless steel or brass. This sphere contains a through-hole, which can be aligned with the valve body's inlet and outlet ports. The valve's handle or actuator allows for the rotation of this spherical element. Here's where the magic happens.

As the valve handle turns, the spherical element can assume three primary positions: fully open, fully closed, or somewhere in between. When fully open, the bore of the valve is aligned with the pipe, allowing unimpeded flow. In the fully closed position, the bore is perpendicular to the pipe, blocking any fluid passage. The real charm, though, lies in the in-between position. This intermediate setting allows precise control over the flow rate, making it ideal for applications where fluid regulation is critical.

The round shape of the ball ensures minimal pressure drop and turbulence, resulting in reduced energy consumption and wear and tear on the valve components. Moreover, ball valves are versatile, compatible with a wide range of fluids and operational conditions. This versatility makes them invaluable in industries such as oil and gas, chemical processing, and water treatment.

In summary, the remarkable efficiency of a flow control ball valve lies in its ingenious design, with a spherical closure element that allows for precise control of fluid flow, minimal pressure loss, and a versatile range of applications. Its ability to handle both high-pressure and high-temperature conditions makes it an indispensable tool in industrial settings where control over fluid flow is essential.

For more information visit chinaoemvalve.